Industries We Serve

WELEXON SAN JOSE

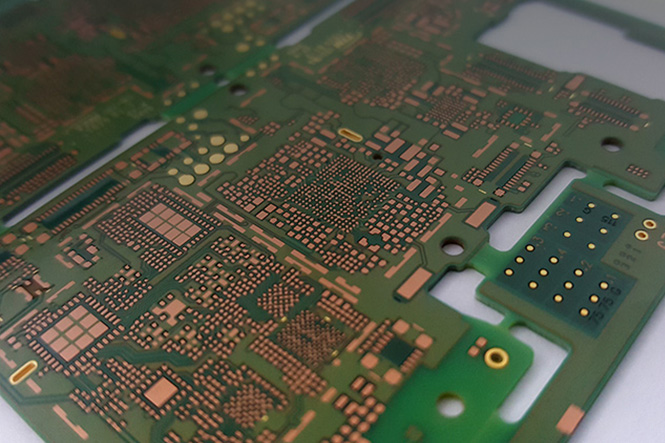

In the heart of Silicon Valley, WELEXON San Jose focuses on advanced technology, ultra quick-turn orders.

- Ultra quick-turn, high-mix, low volume

- Radar with hybrid materials, tight etching, plating controls

- LiDAR utilizing vision drilling and routing

- High layer count requiring high-performance materials, controlled impedance, back-drilling, VIPPO, etc.

- Seamless transfer to Asia volume production

- Diverse laminate materials

WELEXON TORONTO

Just a short distance from Detroit, WELEXON Toronto delivers quick-turn and ramps to low- and mid-volume under one roof.

- Quick-turn, high-mix, low- to mid-volume

- Radar and LiDAR development

- Material development; polyphenylene oxide (PPO), teflon

- Flex, rigid-flex

- Advanced HDI, including 3+n+3

- High layer count requiring high-performance materials, controlled impedance, back-drilling, high aspect ratio plating, VIPPO, etc.

- Seamless transfer to volume production in Asia

- Diverse laminate materials from North America and Asia Pacific