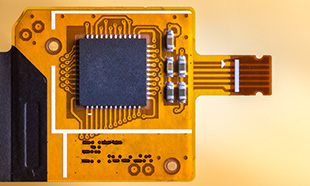

Innovative Engineering and Advanced Process Capabilities

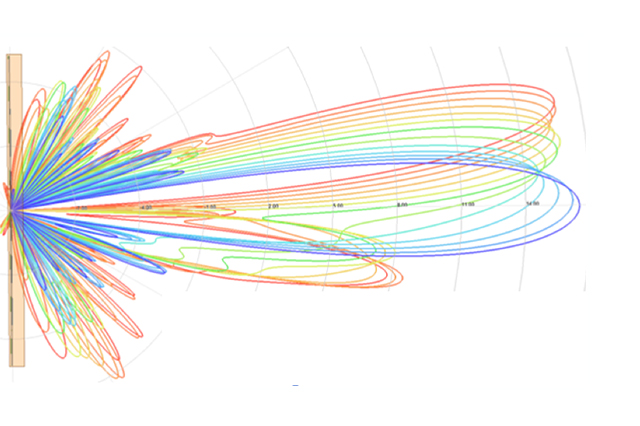

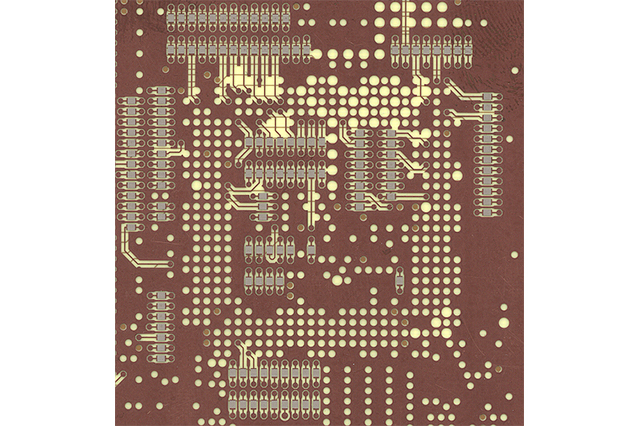

From defense, space, and aerospace electronics, to medical devices, imaging, complex telecommunications

equipment, to 5G enablement, and mmWave automotive radar, WELEXON supports a wide range of frequency bands (L,

S, C,

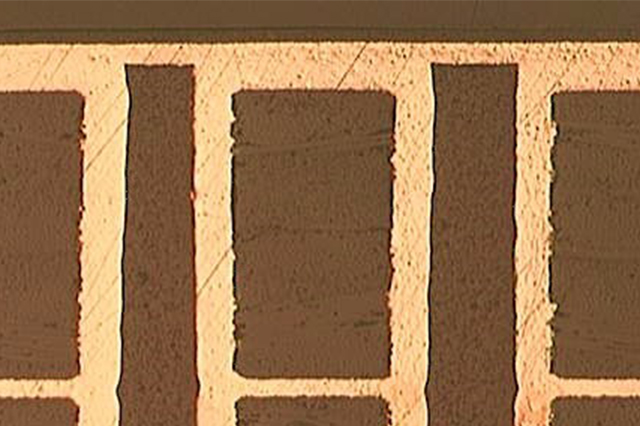

X, Ku, K, Ka, V, W). We have extensive experience with a wide range of low-loss laminate materials and a total

of over 70 resin systems.

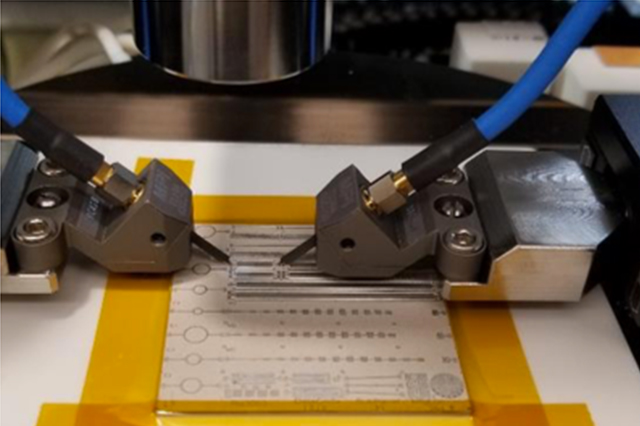

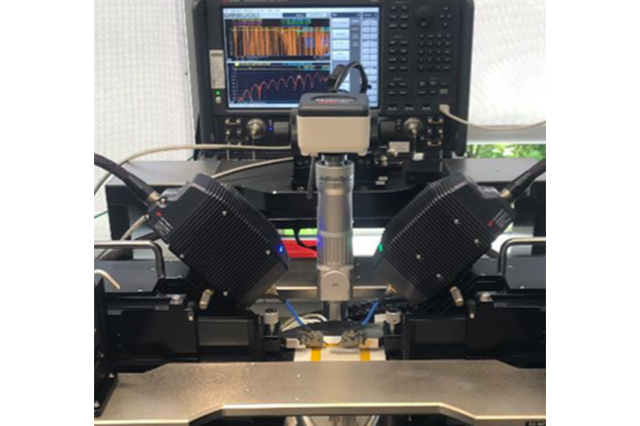

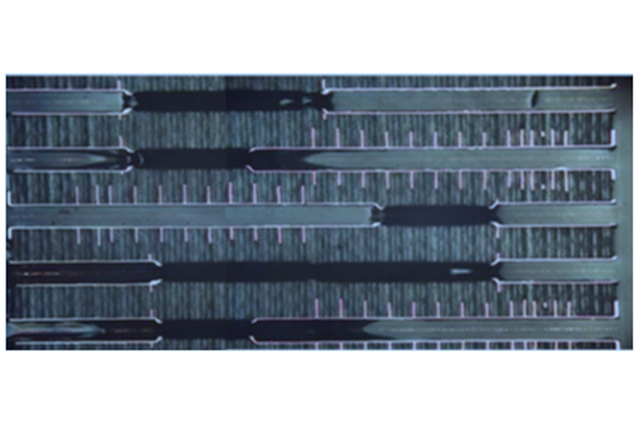

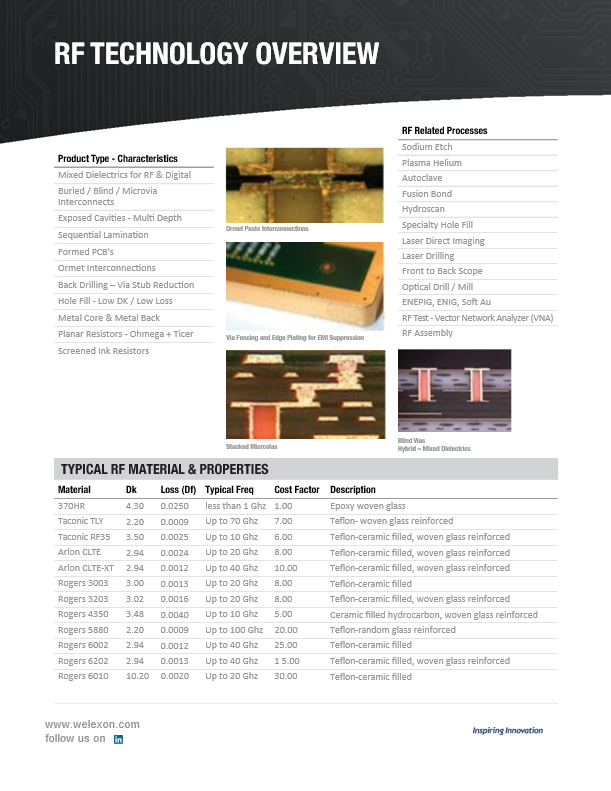

We are investing in research and development to provide our customers with data regarding signal integrity,

materials, and high-reliability design for manufacture guidance to ensure our customers RF/Microwave reliant

applications meet the needs of the market and stringent standards for quality and performance required for

specific industries and reliability in the field. WELEXON has a dedicated Signal Integrity Lab and continues to

provide industry-leading research and development in collaboration with the customers we serve.

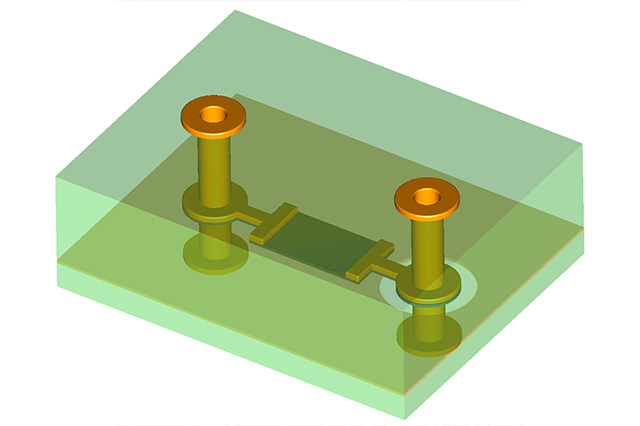

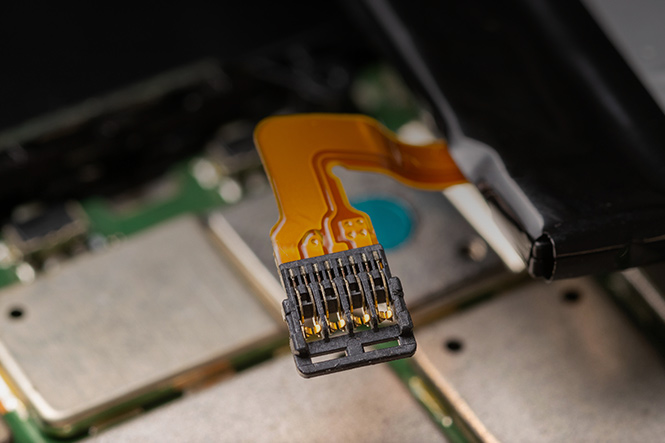

Our broad product offerings and one-stop capabilities provide our customers with complete product lifecycle

support; we have a range of engineered thermal solutions, high-current testing capabilities, low-temperature

cofired ceramics (LTCC) solutions, microwave attenuators, and so much more to ensure we add value at each stage

of the product's journey from NPI to end-of-life. Our rigorous testing and adherence to internationally

recognized quality and environmental standards are just a few reasons why WELEXON's teams are recognized as

exceptional and why leading brands worldwide trust our advanced technology solutions.